Behind the Scenes: A Look at Mercedes-Benz Manufacturing

Many people know that Mercedes-Benz originated in Germany, but it may come as a surprise that the automaker also produces some of the world’s finest luxury automobiles right here in the US. Since the 1990s, the Mercedes-Benz U.S. International (MBUSI) plant in Tuscaloosa County, Alabama has produced millions of the highest quality vehicles using a combination of American, Japanese, and German automotive best practices.

Mercedes-Benz U.S. International

Today, MBUSI produces four of the most popular Mercedes-Benz models: both the GLS and GLE SUVs, the GLE Coupe, and most recently the all-new C-Class. Thanks to Daimler AG’s continued investment of over $4.5 billion, MBUSI can boast responsibility of more than 22,000 direct and indirect jobs in the region with more than $1.5 billion in regional economic impact.

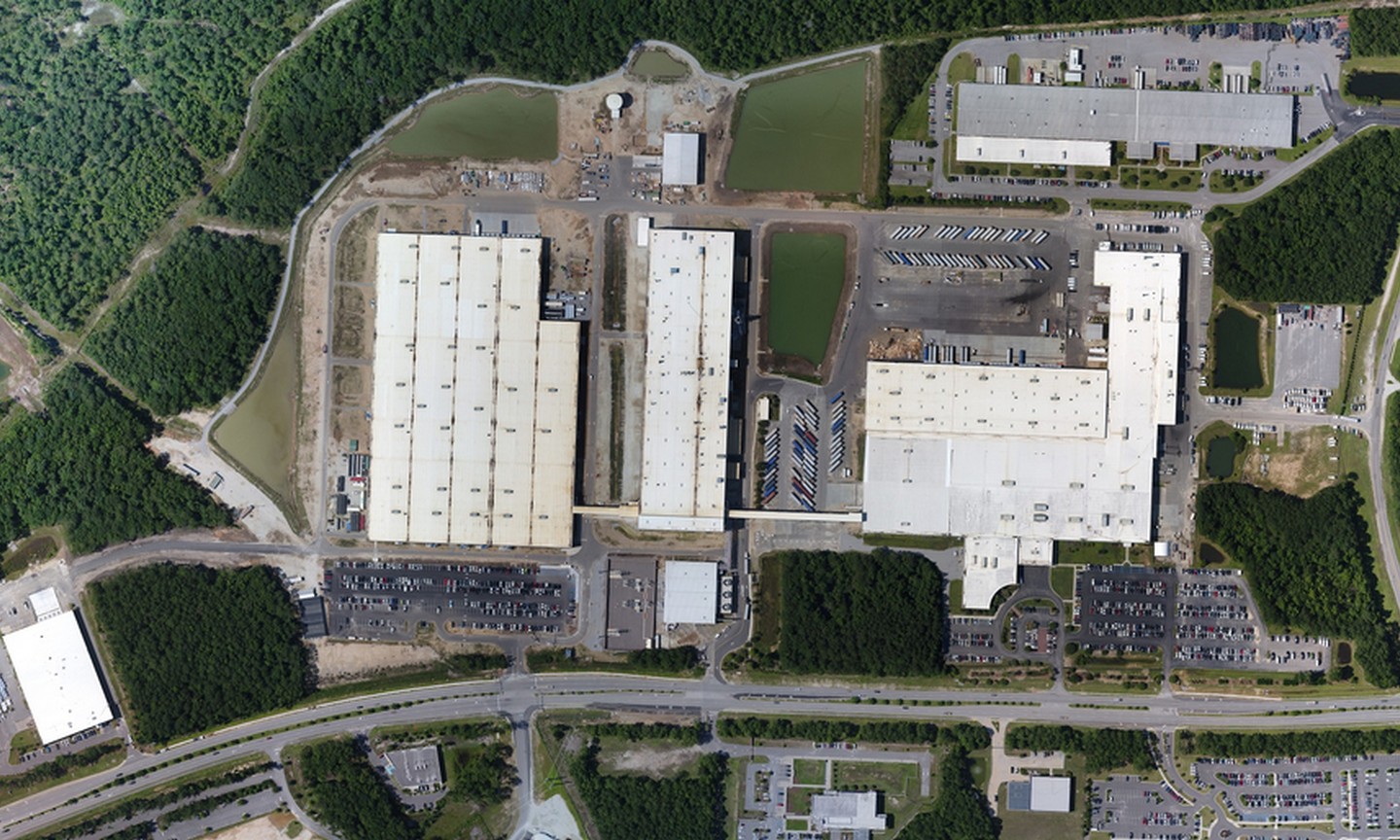

The 1000-acre MBUSI site (pictured above) includes over 5 million square feet of top-tier luxury-car manufacturing space. Not only does the plant showcase the leading edge of manufacturing technology; it also stays committed to the corporate leadership in sustainable environmental impact. Every month, MBUSI aims for aggressive targets for more ecologically responsible policies concerning water consumption, hazardous waste, electricity costs, natural gas consumption, and recycling rates. In fact, the MBUSI plant is ISO 14001 Environmental Management System Standard certified, and it is a “Zero Waste to Landfill” certified manufacturer, meaning all waste from the facility—from manufacturing scrap to the food waste from the cafeteria—gets recycled or turned into energy; absolutely nothing goes to the landfill.

The manufacturing process at MBUSI was designed to be flexible, producing each model “Just In Time,” which results in an agile assembly line that can quickly adjust to market demands and model changes. This is one of the reasons Mercedes-Benz models can reflect the latest technology changes each year. Instead of being stuck with a single template to use for a model generation for several years, the assembly line can easily react to smaller updates for each model year.

The MBUSI campus also houses a comprehensive visitor center, which showcases a world of information about Mercedes-Benz production and brand history. For more information on MBUSI plant tours, visit the MBUSI Visitor Center website here.

AMG Affalterbach: Birthplace of Mercedes-Benz Supercars

Fans of Mercedes-AMG, the automaker’s high-performance lineup, may find a mecca in Affalterbach, Germany. The AMG Affalterbach factory represents one of the most sophisticated automotive manufacturing centers in the world. Visitors can see state-of-the-art technology and enjoy hours of luxury comfort and performance experiences:

You can learn more about visiting the AMG Affalterbach factory for tours or even vehicle pickup on the factory's website here.

Industrie 4.0

Mercedes-Benz knows that the future of automotive manufacturing lies in the combination of human craftsmanship and robotic abilities. That’s why the automaker is already looking forward to creating “smart factories” that utilize the latest advances in digitalization and robotics, what Mercedes-Benz calls “Industrie 4.0.”

At Mercedes-Benz, we use the term 'Industrie 4.0' to describe the digitalization of the entire value chain, from design and development to production, where the term has its origin, and finally to sales and service. For us at Daimler, there is no question that the digital revolution will fundamentally change our industry. This applies to the methods by which we develop, plan and produce our vehicles. It applies to the way we make contact with our customers. And not least, it can be experienced through our products themselves.

- Markus Schäfer, Member of the Divisional Board Mercedes-Benz Cars, Manufacturing and Supply Chain Management, Daimler AG

At the end of the day, digitalization will allow for even greater flexibility, efficiency, and speed, as well as a more attractive working environment. This synergy of new technologies like 3D printing, human augmentation, machine learning, and cloud data networking will create a smart factory for the modern age. The end result? A higher quality product for the consumer.

The future of luxury automotive driving is already here at Mercedes-Benz of Owings Mills. We have the end result of all the cutting-edge manufacturing described above on our showroom floor, waiting for you. Check our latest inventory of high-end driving machines, then contact our sales staff online to schedule a test drive and experience the product of Mercedes-Benz manufacturing.

Image and Video Credit: Mercedes-Benz